I. Introduction

After a sheet metal part is bent, its actual size may differ from the size depicted on its flat pattern drawing. This is due to the external tension that stretches the sheet and internal compression caused by extrusion.

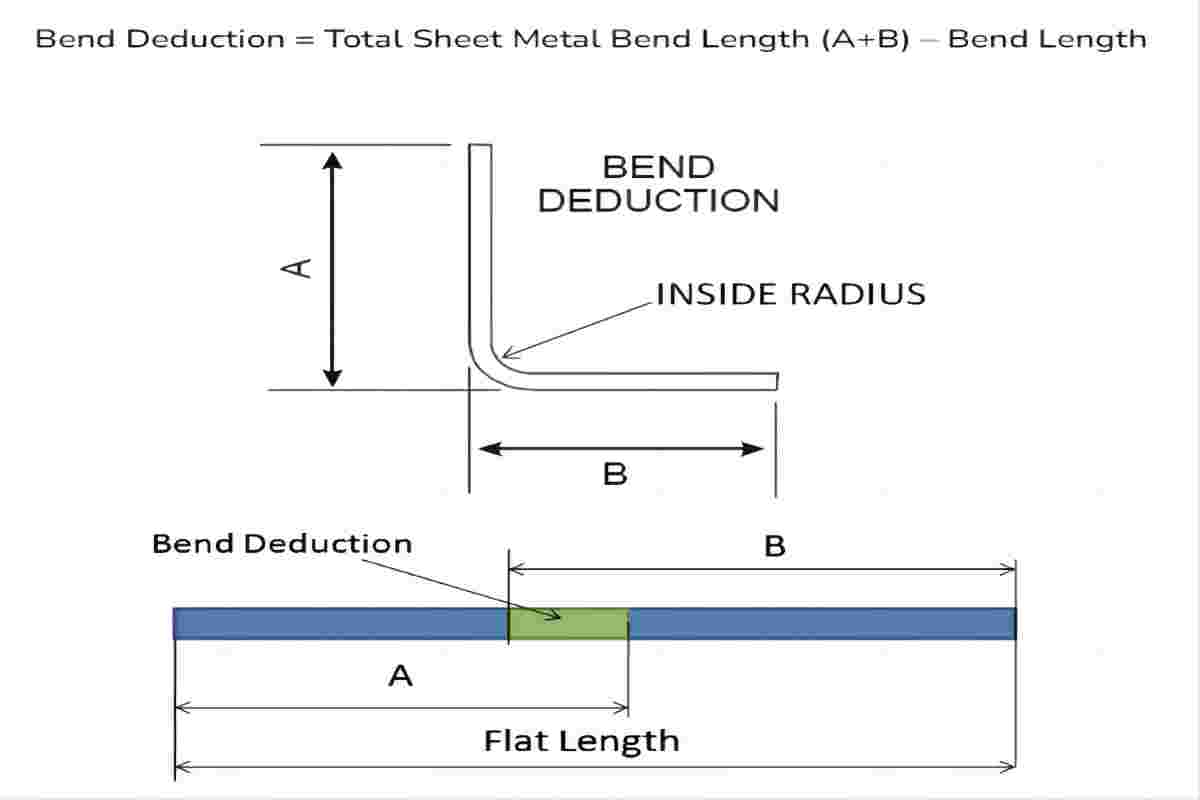

The total length increases, so it's essential to calculate the sheet metal bend deduction. Bend deduction is the difference between the total length of the flanges after bending and the total flat length. We discussed the bend allowance and bend deduction calculation in a previous article.

The bend deduction is often confused with bend allowance. Thus, understanding the bend allowance or bend deduction is a crucial first step to understanding how sheet metal parts are fabricated for the metal forming and fabricating industry.

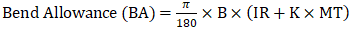

1. Bend allowance calculation formula:

The bend allowance is the amount of the neutral axis that bends. The bend allowance formula takes into account the geometries of bending and the properties of your metal to determine the bend allowance.

2. Formula for bend deduction:

Where:

- RÂ is the bend radius

- TÂ is the material thickness

- BÂ is the bend angle

- IRÂ is the inside radius

- KÂ is the K-factor

- MTÂ is the material thickness

- OSSB is the outside set back.

The bend deduction is defined as the material you will have to remove from the total length of your flanges to arrive at the flat pattern. Protective coatings, variations in the alloy and thickness as well as many other small factors all add up to give you bend deductions unique to your operation.Â

3. Example calculation

Assume we have a metal sheet with a thickness of 2 mm, a bend radius of 3 mm, a bend angle of 90 degrees, a K factor of 0.3, and an inside radius of 3 mm. We need to calculate consequently the bend deduction.

Substituting the values:

Calculate each part:

So:

Calculate the second part:

Final calculation:

This calculation formula is used to develop the flat pattern length of sheet metal and the size of the workpiece.

The bending chart provides an intuitive way to visualize the effect of different parameters such as bend angle, material thickness, inside radius and k-factor, etc. The material thickness will be measured in decimal form, not by the gauge number.

To determine the bend angle properly you must use the complementary angle of the part feature. It is important to convert the included angle to the complimentary angle before you perform the calculation. The inside radius will be the finished radius of the included angle.

For instance, if the bend angle is known to be 90 degrees, you can refer to the 90 degree bend deduction chart to find the desired parameters. The below Microsoft Excel chart is for even numbered gauges 8 through 24 and has a default K-Factor of .33 for each.

Many software packages like Solid Works and Solid Edge will let you incorporate a bend deduction chart into its calculations when you develop a flat pattern. As you can see the bend deduction calculator is below, which can also serve as a simple bend allowance calculator:

Miño, L. Bend Allowance Calculator. Available at: https://www.omnicalculator.com/physics/bend-allowance. Accessed: Jun 20, 2024.4. K factor

The K-Factor is a property of the material substrate you are bending. This property reflects how the material stretches when formed, and will vary depending on the bend method.

II. Conclusion

The value of bend deduction can be calculated not only through a formula but also using a deduction chart. To gain further knowledge about sheet metal bending, you can explore the ADH website blog for more informative content and products.

We have over 20 years of experience manufacturing hydraulic press brakes, shears, and fiber laser cutting machines, which are highly performance and efficient. Get an instant quote for your precision sheet metal fabrication projects now!

III. FAQs

What Is Bend Deduction and Bend Allowance?

How to Calculate Bend Deduction?

Bend Allowance Chart

Ribbed V Belt Volvo B 9,V Belt Ribbed Volvo B 9,Automotive Ribbed V Belt Volvo B 9,Ribbed V Belt For Volvo 9700

ZHEJIANG AOSITE AUTO PARTS CO.,LTD , https://www.aositebelt.com